Corrosion status of reinforced concrete in harsh environment

Concrete structures inevitably have cracks due to the role of internal and external factors, and cracks are the main reasons for the reduction of the bearing capacity, durability and water resistance of concrete structures. Preventing cracks from causing adverse effects on concrete structures is one of the most needed functions of concrete coatings. Whether the coating has the ability to follow the crack extension of concrete is the most critical index to measure the protective performance of concrete coating.

Pictures of various types of reinforced concrete corrosion in harsh environments

Through the research of different anti-corrosion coatings in the laboratory, our company has successfully developed a set of concrete coatings with high flexibility - reinforced concrete flexible anti-corrosion coatings, which has excellent crack tracking.

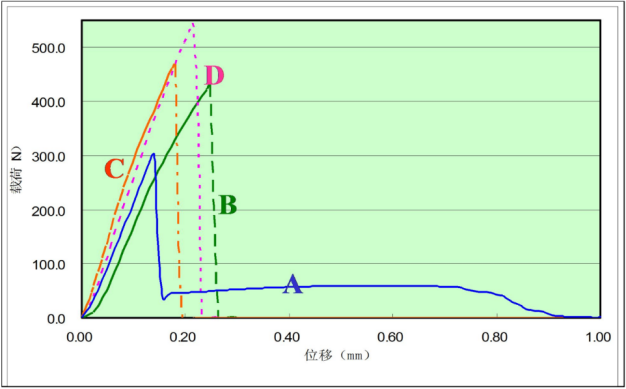

Crack following performance of our flexible coatings (A) compared with other coatings (B, C, D)

Through the comparison experiment of crack following performance with other coatings, it can be clearly seen from the figure that the flexible coating developed by our company has excellent crack following performance. Other coatings will completely crack when the displacement of 0.2-0.3mm occurs, while our flexible coating will crack only when the displacement of 0.8mm occurs.

Our flexible coatings (right) compared with other coatings (left) flexibility

Through the flexibility comparison experiment, it can be clearly seen that after coating the flexible coating developed by our company, the flexible substrate can still bend freely, showing excellent flexibility properties. However, after coating other coatings on the same flexible substrate, the flexible substrate loses its original flexibility and becomes hard and difficult to bend.